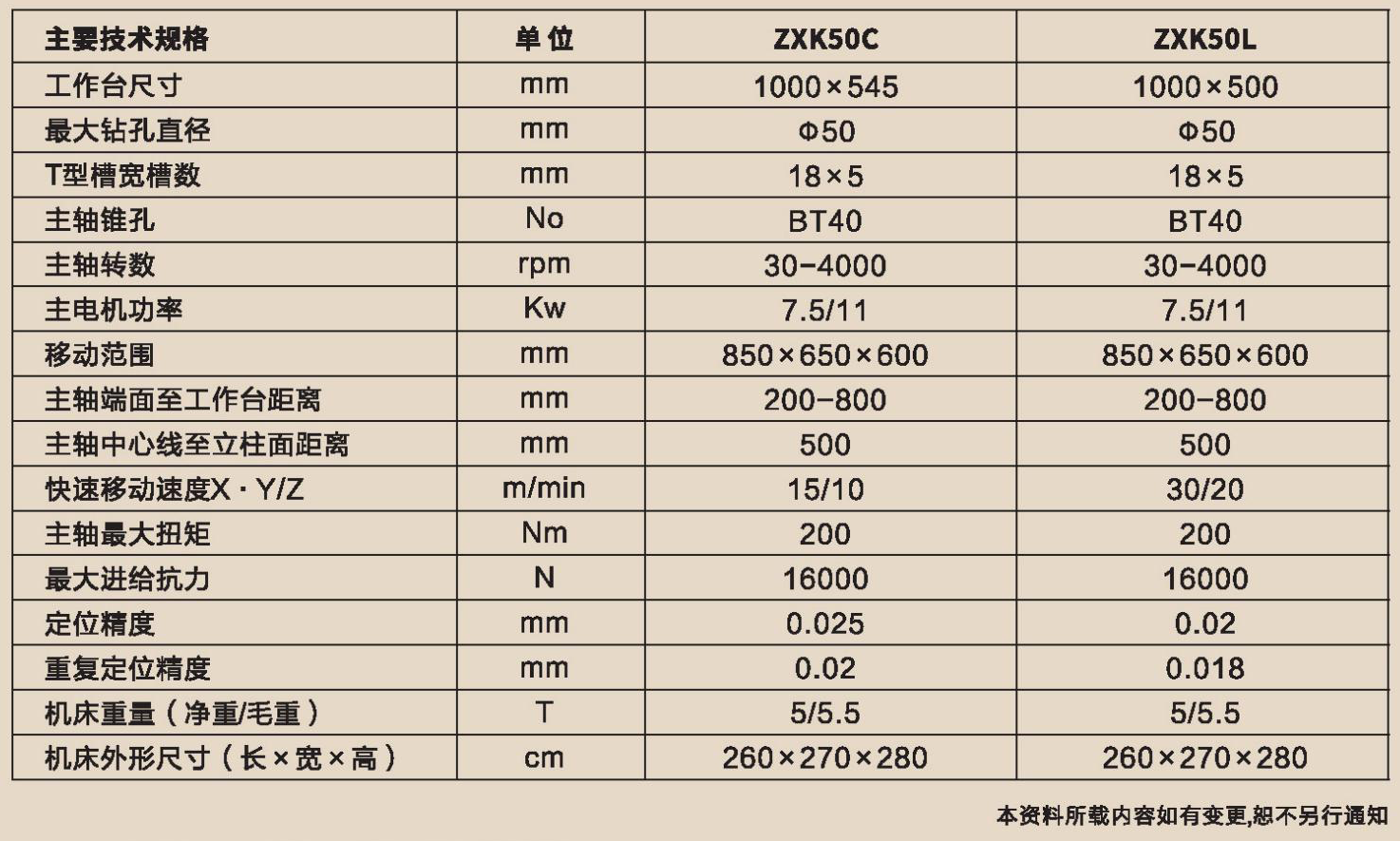

ZXK50L CNC Drilling and Milling Center

The ZXK50C, ZXK50L, and ZXK80C CNC drilling iron center series products are widely used in industries such as military, automotive, railway, bridge, rock drilling, locomotive, and petroleum, focusing on efficient machining of parts with high torque and heavy cutting.

▪ The basic components of the machine tool are made of special castings, and the bed and slide of the vertical machining center are used, thus having a high rigidity structure.

▪ The guide rail and worktable are both quenched and ground, and coated with matching guide rails. Automatic intermittent lubrication ensures smooth feed without crawling, and good precision retention. The three axes of the machine tool are all driven by ball screws, and the connection between the motor and the screw is direct.

▪ Configure Guangzhou CNC GSK980Didi CNC system or Hewan Advantech Baoyuan M5800 CNC system, supporting milling, boring, and drilling cycle machining.

▪ 8. Wide screen color LCD display, more user-friendly operation.

▪ The full gear transmission of the Fengzhou box enhances the rigidity of the machine tool, allowing for strong cutting and tapping capabilities: M30. Configure a 16/24 cam robotic arm tool changing magazine to achieve high-speed automatic tool changing function in automatic machining.

▪ The three coordinate drive devices are all DA98 series digital servos produced by Guangzhou CNC Company, and the spindle servo is DAY3 series digital spindle servo produced by Guangzhou CNC Company.

Copyright © DAHE CNC MACHINE CO.,LTD. All Rights Reserved. 宁ICP备11000124号 Technical Support: Golden Hammer New Media