TM-50 integrated boring and honing machining center

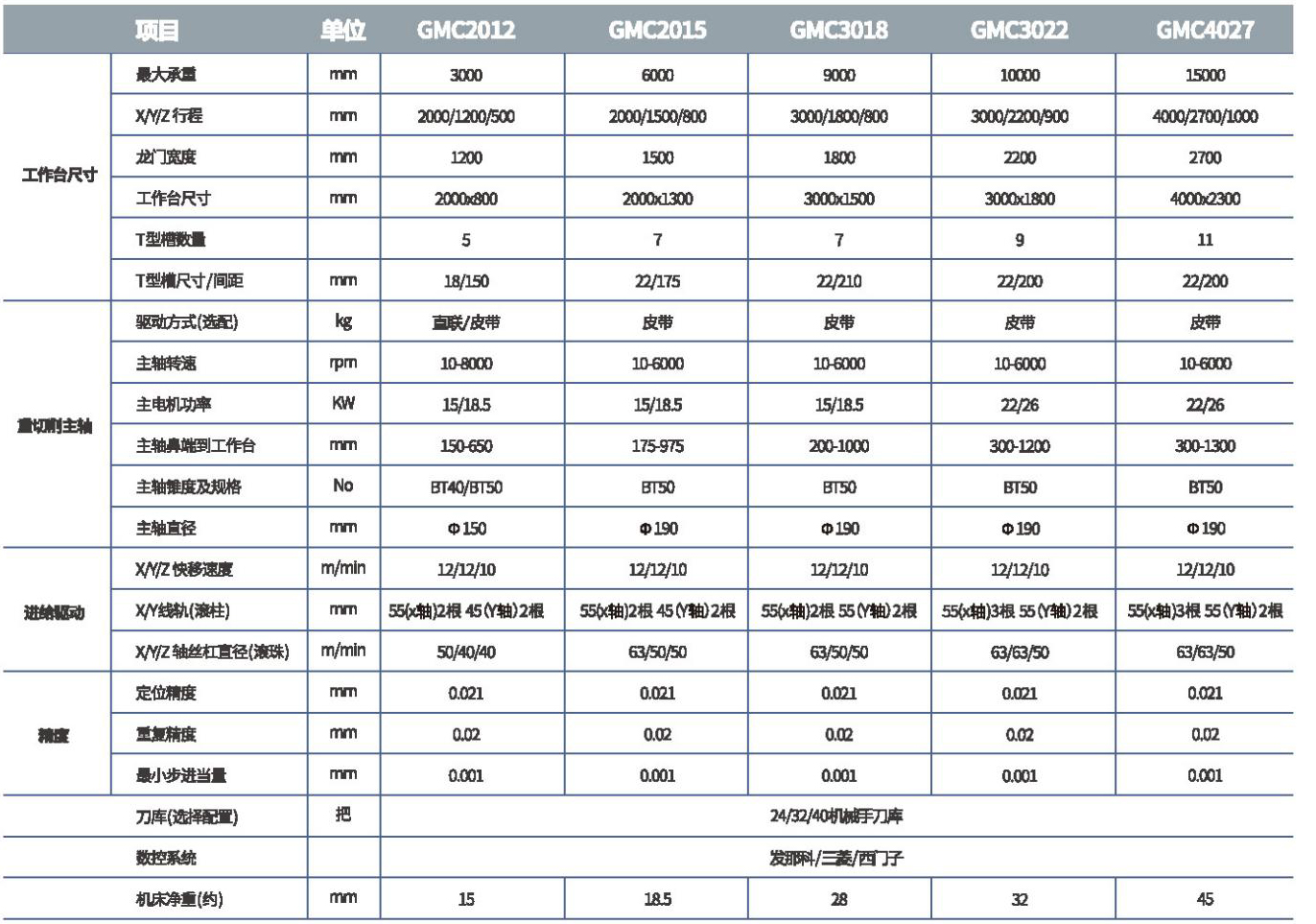

Longmen type machining center is a new generation of Longmen type machining center developed by Ningxia Yinchuan Dahe CNC Machine Tool Co., Ltd. through continuous innovation and performance improvement, based on market and customer needs, and absorbing advanced concepts from international and domestic manufacturers. This machine tool is used for milling, drilling, reaming, boring, reaming, countersunking, drilling and countersunking head holes, boring, threading, and various milling processes in mechanical processing. It is suitable for workpieces made of steel, cast iron, stainless steel, and other materials. The machine tool has high efficiency and high positional accuracy.

The machine has flexible configuration and diverse options to meet different customer requirements; All major components of the host are designed with a closed box structure, thick walled and multi reinforced, high-quality gray cast iron resin sand casting, and undergo multiple stress relief processes. The X-axis is equipped with a double-sided spiral chip removal device, and the axis return to zero is equipped with a chain conveyor for efficient chip removal and environmental protection. The X/Y/Z axis adopts linear roller guide rails, which can achieve high-speed and precise positioning; Ensure efficient drilling, milling, and other heavy cutting processes.

The standard configuration of the tool magazine is a 20/24 cam manipulator type: multiple functional components such as grating ruler full closed-loop, workpiece measurement, tool measurement, etc. can be configured according to needs.

The standard configuration of this machine includes CNC systems such as FANUC, which have functions such as linear/arc/spiral interpolation, three-axis linkage (configurable with a four axis system), rigid tapping, graphic display, coordinate system setting, tool offset, fixed cycle, fault diagnosis, error compensation, program transmission and storage (CF card interface), etc. The PLC software of the machine tool electrical control system adopts modular design, which facilitates customers to add functional components at any time; The high rigidity spindle unit is driven by a high-power 15/18.5kW spindle motor, with a maximum spindle speed of 8000r/min, which can meet the requirements of high-speed and high-precision machining.

The machine tool has good dynamic performance, accurate motion accuracy control, stable machining accuracy, and good maintenance; The parts can automatically complete various processes such as iron, drilling, expanding, boring, reaming, tapping, etc. in one clamping; It is convenient to use, operate, and maintain, especially suitable for batch processing of parts, and is the preferred equipment for mechanical manufacturing industries such as automotive and motorcycle parts, military industry, valves, textiles, printing and packaging, molds, and vocational education training and teaching.

Copyright © DAHE CNC MACHINE CO.,LTD. All Rights Reserved. 宁ICP备11000124号 Technical Support: Golden Hammer New Media