DHK1160 vertical CNC honing machine

In 2020, the full implementation of the National V1 emission standard for automobiles is imminent, and the development of more National VI products is urgent. It is necessary to establish new production lines and improve manufacturing levels to meet the demand for IT5 level precision products required by customers.

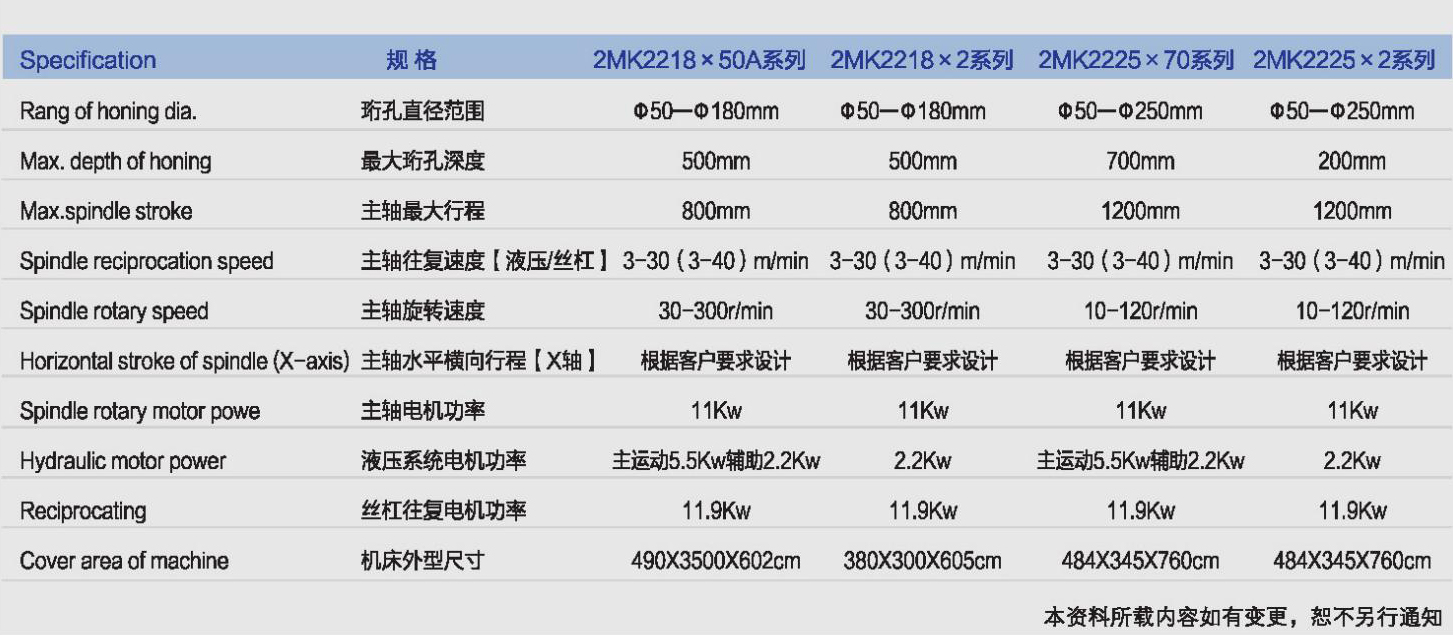

Due to the improvement of product accuracy level, it is necessary to increase the DRHE multi pass honing process to enhance product accuracy. Multiple honing machines connected in series occupy a large area, and the use of dual axis honing machines can reduce site occupation and improve product accuracy. 2MK2218X2 dual spindle honing machine, with a center distance of 500mm between the two spindles, occupies a small area and can achieve honing processing of different sizes at two workstations (two processes), as well as honing processing of the same size at two workstations (the same process). It can also achieve program control switching between the two processing methods, switching to single feed mode when two honing operations are required and switching to dual feed mode when one honing operation is required, which is convenient and fast. The machine tool adopts a honing CNC control system developed in cooperation between Dahe CNC and Guangzhou CNC. The dual spindle is used for simultaneous machining and measurement, which not only improves the efficiency of honing machining, but also enhances the accuracy index of machining, meeting the requirements of industry quality upgrading.

Copyright © DAHE CNC MACHINE CO.,LTD. All Rights Reserved. 宁ICP备11000124号 Technical Support: Golden Hammer New Media